Force

In general force is a Push or Pull, which

creates motion or tends to create motion, destroy or tends to destroys motion.

In engineering mechanics force is the action of one body on another.

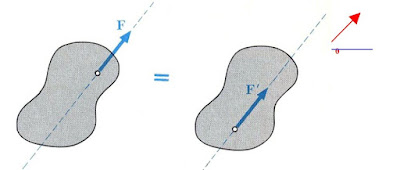

A force tends to move a body in the direction

of its action, A force is characterized by its point of application, magnitude,

and direction, i.e. a force is a vector quantity.

Force exerted on body has following two effects

1. The external effect, which is tendency to change the motion of the body or to develop

resisting forces in the body

2. The internal effect, which is the tendency to deform the body. If the force system

acting on a body produces no external effect, the forces are said to be in balance and the body experience no change in motion is said to be in equilibrium.

Units of force

The following force units are frequently used.

A. Newton

The S.I unit of force is Newton and denoted by

N. which may be defined as

1N = 1 kg. 1 m/s2

B. Dynes

Dyne is the C.G.S unit of force.

1 Dyne = 1 g. 1 cm/s2

One Newton force = 102 dyne

C. Pounds

The FPS unit of force is pound.

1 lbf = 1 lbm. 1ft/s2

One pound force = 4.448 N

One dyne force = 2.248 x 10ˉ6 lbs

Systems of forces

When numbers of forces acting on the body then

it is said to be system of forces

Types of system of forces

1. Collinear forces :

In this system, line of action of forces act

along the same line is called collinear forces. For example consider a rope is

being pulled by two players as shown in figure

2. Coplanar forces

When all forces acting on

the body are in the same plane the forces are coplanar

3. Coplanar Concurrent force system

A concurrent force system contains forces whose

lines-of action meet at same one

point. Forces may be tensile (pulling) or Forces may be compressive

(pushing)

4. Non Concurrent Co-Planar Forces

A system of forces acting on the same plane but

whose line of action does not pass through the same point is known as non-concurrent

coplanar forces or system for example a ladder resting against a wall and a man

is standing on the rung but not on the centre of gravity.

5. Coplanar parallel forces

When the forces acting on the body are in the

same plane but their line of actions are parallel to each other known as

coplanar parallel forces for example forces acting on the beams and two boys

are sitting on the sea saw.

6. Non coplanar parallel forces

In this case all the forces are parallel to each

other but not in the same plane, for example the force acting on the table when

a book is kept on it.